Driving Packaging Innovation

Transforming Busy Food Categories

At Innavisions, innovation is driven by the realities of food manufacturing. We apply technical expertise and practical insight to develop packaging formats that help brands balance performance, efficiency and sustainability in a demanding market. As requirements around lightweight design, recyclability and cost continue to evolve, our focus is on creating solutions that support production efficiency while delivering the quality and consistency customers expect.

Shaping Better Packaging Solutions Together

Our approach to innovation brings together technical development, customer collaboration and a clear focus on performance. We work closely with BRC-accredited manufacturing partners who understand the regulatory, efficiency and risk considerations involved in developing packaging for food manufacturing. This ensures new and improved formats not only meet compliance requirements, but also support sustainability goals and reliable performance on the line.

Alongside this, we work directly with customers to improve packaging performance and the consumer experience. Whether the aim is to stand out on shelf, reduce material use, improve efficiency or enhance product protection, we apply practical design insight to develop solutions that add real value. Through thoughtful innovation, we help brands remain competitive while delivering packaging that performs across production, distribution and end use.

1

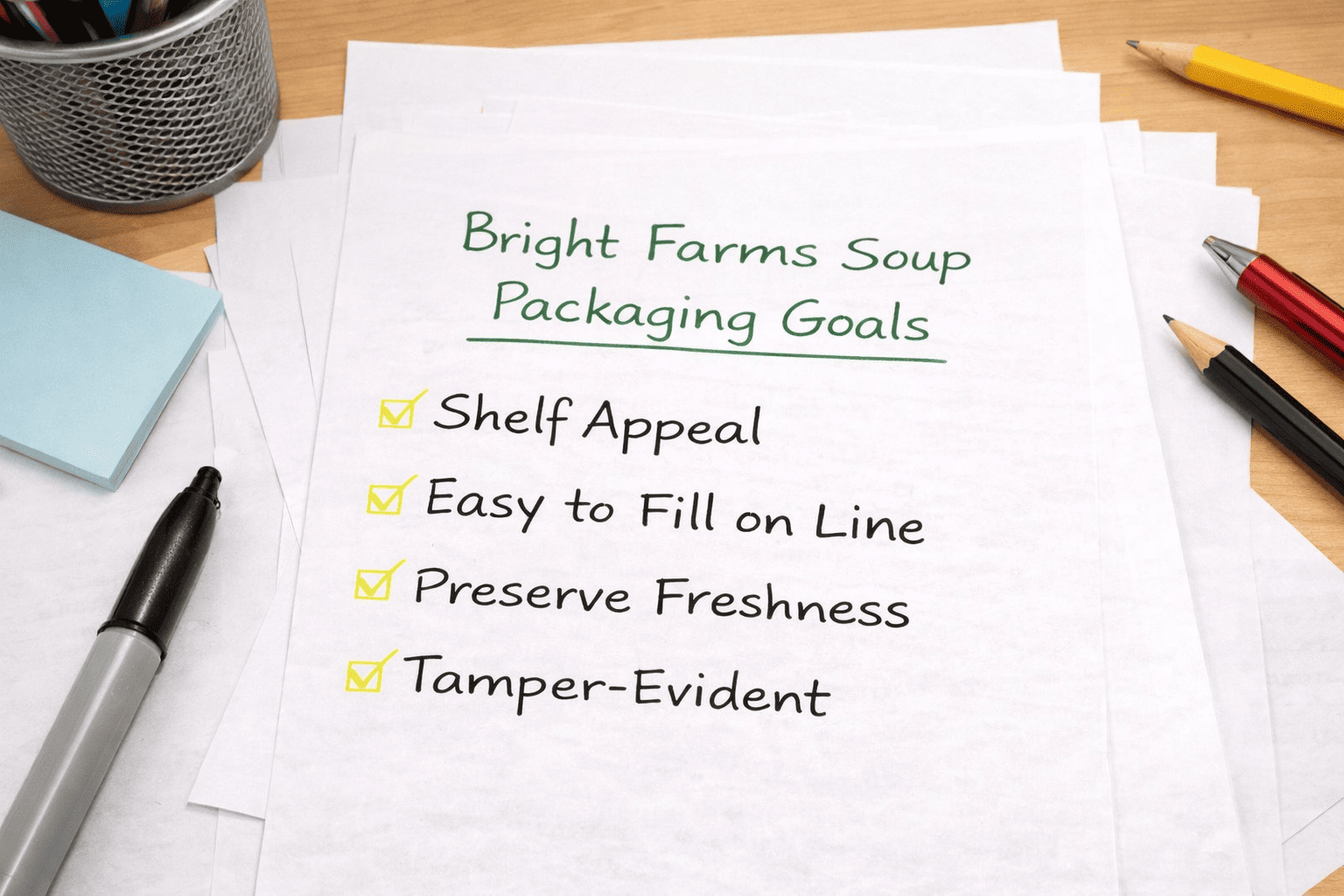

Step 1: Understanding the Brief

We define what the pack needs to achieve, from filling and storage to shelf life, and where innovation can add value.

2

Step 2: Category Insight

We review current packs, consumer expectations, material developments and emerging trends.

3

Step 3: Define Success

We agree what success looks like, considering performance, experience, sustainability, manufacturing and cost.

4

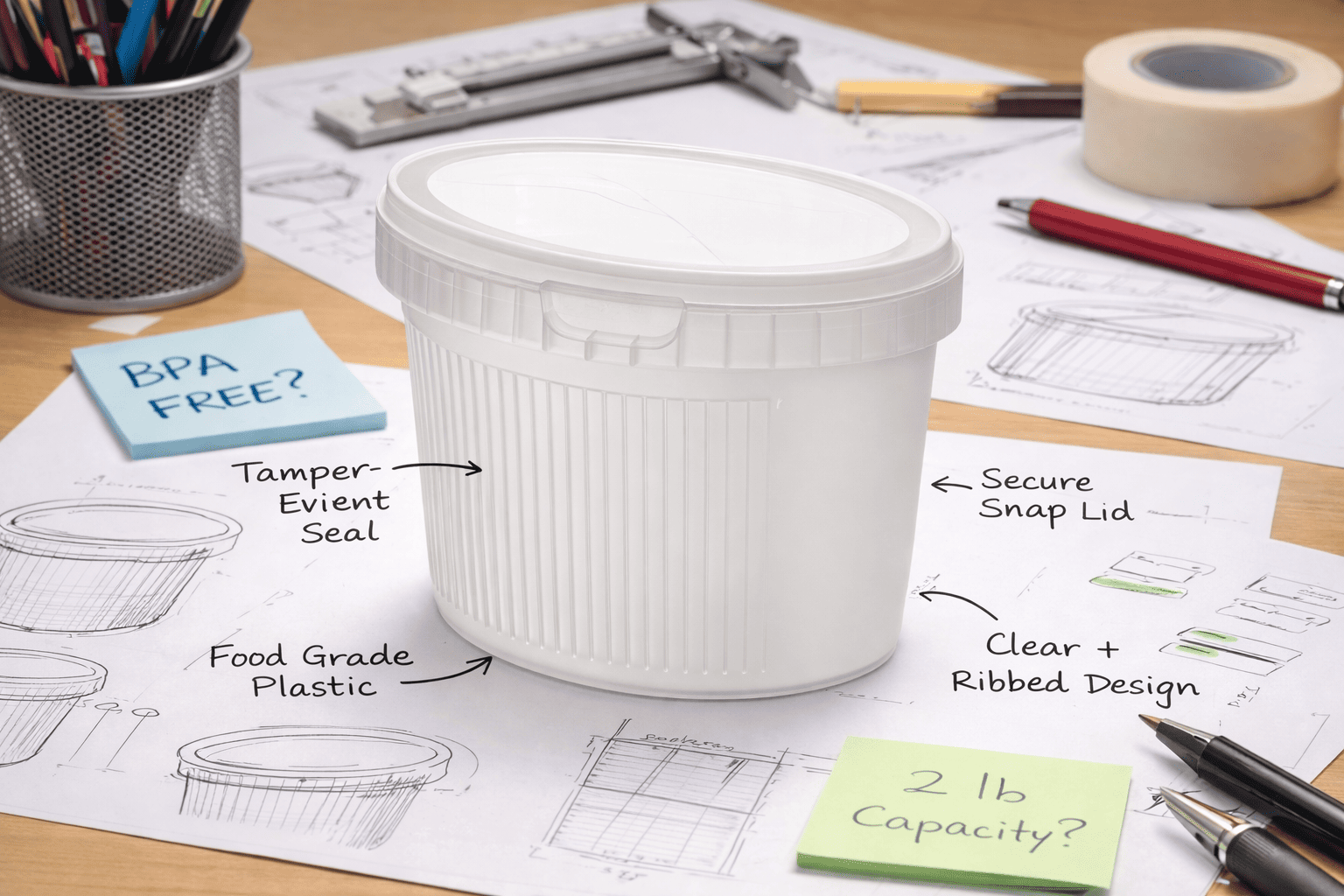

Step 4: Exploring Tooling Options

We assess tooling requirements, line capabilities and future growth to ensure long-term fit.

5

Step 5: Quotation and Specification

We provide clear pricing, detailed specifications and drawings for the proposed concept.

6

Sampling and Evaluation

Prototypes are produced to assess size, feel and shelf presence before final decisions.

7

Final Development

Materials, tooling, costs and packaging details are confirmed ahead of production.

8

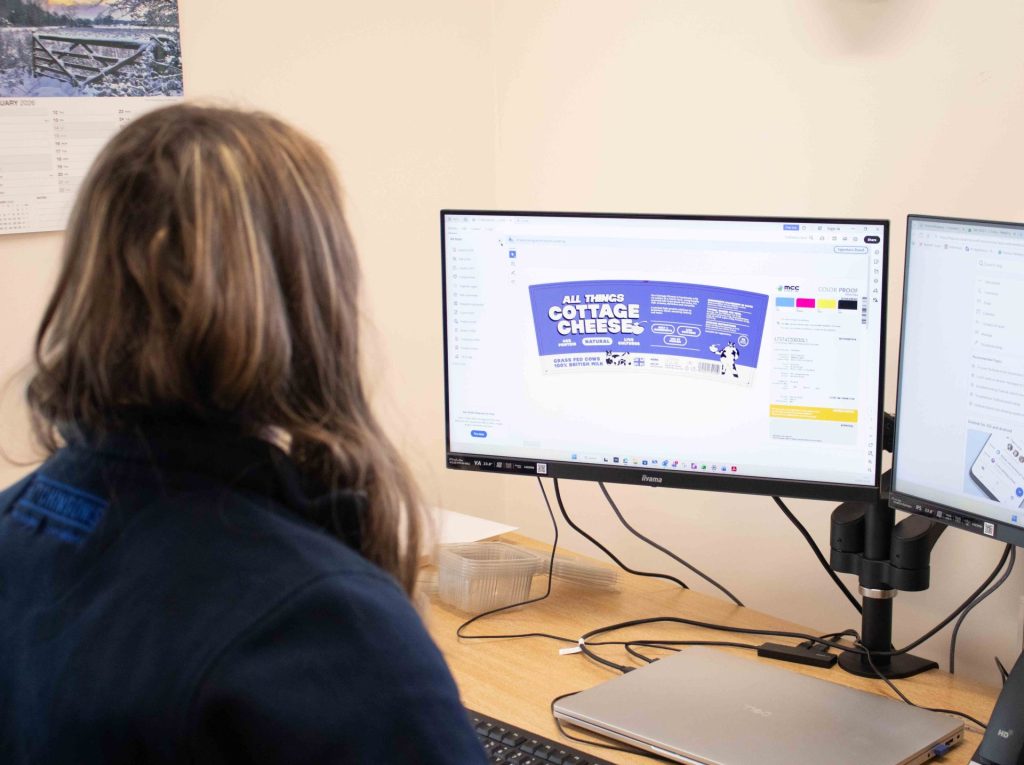

Finished Product

Colours and label finishes are matched and approved, ready for manufacture and launch.